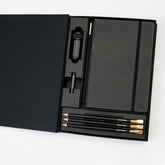

How It's Made: Blackwing Pencils

by

Sadie Giacomelli

18 Feb 2025

The Blackwing Pencil Making Process

Here's a quick behind-the-scenes look at how Blackwing pencils are made, broken down step-by-step!

- Incense-cedar lumber is cut into blocks and then slats that are a bit longer than the length of a finished pencil.

- A groover machine cuts grooves into the slats. This is where the graphite goes.

- The graphite cores - made from a mixture of graphite, wax, and clay - are placed into the grooves.

- A second grooved slat is glued on to the first, making a "sandwich." The sandwiches are clamped and allowed to dry before moving on to the shaping process.

- The sandwiches are trimmed and sent through the shaper. Each sandwich produces eight hexagonal pencil sticks.

- The pencil sticks are passed through a paint line. Blackwing pencils receive 10+ layers of lacquer to achieve their signature finish.

- The painted pencils are imprinted using a hot-stamp machine that gives them their distinct gold foil branding.

- The finished sticks are shaved and tipped with the iconic Blackwing ferrule and eraser.